一:Machine model name

Model:W10nc-4x1500

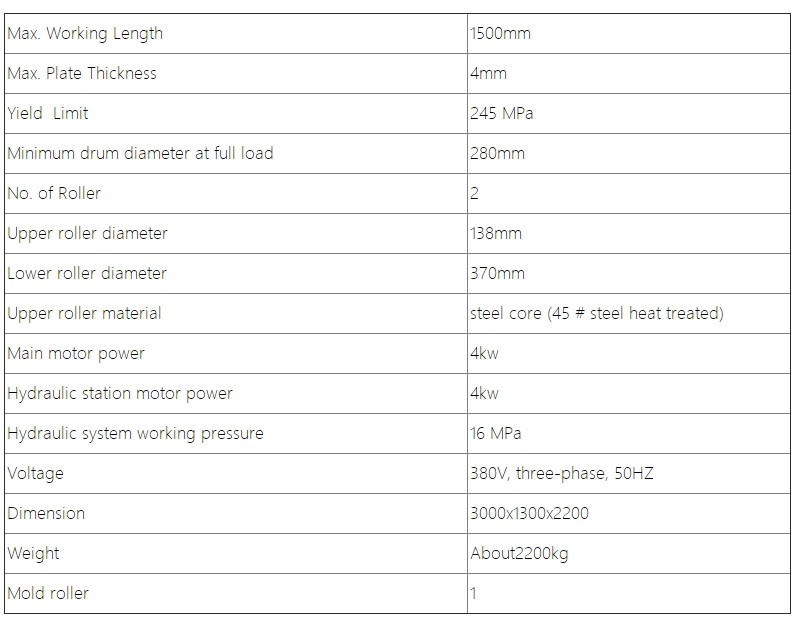

二:Main parameters

三、 The purpose of the machine:

This machine is a dedicated two roll plate bending machine used for the bending and forming of metal sheets. It can load metal sheets in one go without turning the head to complete the bending and rolling of the two ends of the sheet, and roll them into circular or arc-shaped workpieces within a certain range. This machine is the most ideal bending and forming equipment in industries such as petroleum, chemical, boiler, shipbuilding, locomotive and vehicle, metal structure and mechanism manufacturing.

四、 Overview of Machine Structure

The lower roller of this machine is the active roller, and the upper roller is the driven roller. The position of the upper roller is fixed, and the lower roller can be lifted and moved. The lower roller lifting is driven by two end oil cylinders, which can be lifted separately or simultaneously. The electrical control and operation are centrally controlled by the electrical system control panel located next to the machine. To facilitate the unloading of the formed cylindrical workpiece, the tilting bearing body on the left end of the roller on the machine is controlled by hydraulic transmission for tilting and resetting.

1. Transmission principle

The lower roll of this machine rotates actively, while the upper roll is a driven roll. Its rotation is driven by the friction between the steel plate and each roll, and bearings are used at the shaft diameter of each roll.

2. Main transmission mechanism

The lower roller of this machine is the main driving roller, and the reducer drives the lower roller to rotate at a linear speed of 4 meters per minute.

3. Left and right racks

The left and right frames are the main body of the two roll plate rolling machine, which adopts a welding structure and aging treatment. They are installed on the overall welding base to ensure sufficient strength and stability.

4. Upper and lower roller shafts

The material of the upper roller is 45 # steel, which has undergone quenching and tempering treatment. The surface hardness is HRC48-52, and the comprehensive performance is good, in accordance with the relevant provisions of JB3185-82 Technical Conditions for Small and Medium Three Roll Plate Rolling Machines. The lower roller is made of steel core reinforced polyurethane, with a single-sided thickness of 50mm.

5. Inverting and resetting the transmission structure

The flipping and resetting of the front bearing body of the upper roller is driven by a hydraulic oil cylinder, which is fast, convenient, and safe to operate.

6. Electric motor and hydraulic power motor

The main motor and hydraulic motor work smoothly and have reliable quality.

7. Lubrication

According to the operating conditions of the machine, two methods are adopted: box lubrication and regular oil lubrication.

The sliding guide surface, upper roller, lower roller, and side roller shaft diameter are regularly lubricated with oil cups.

The cycloidal pinwheel reducer of the lower roller main drive adopts box lubrication.

9. Security protection system

To ensure the safe and convenient use and maintenance of the equipment, protective covers have been installed strictly in accordance with relevant safety technical requirements and standards; In order to ensure that the power can be quickly cut off in case of accidents, emergency stop buttons are set up on the control console and mobile handle according to standard requirements; Equipped with overcurrent, overheating, overload, short circuit protection, safe and reliable, and safe operation; There are various warning signs, nameplates, and text prompts installed on protective fences, electrical cabinets, and other parts.

五、 The electrical control system of the machine:

1. Structural composition:

The main components of the strong current part of the electrical system are selected from products with good performance both domestically and internationally.

2. Main technical indicators of the system:

The working voltage of the system is 380V, 50HZ;

The ambient temperature is -5~45 ℃;

The relative humidity is between 5% and 85%.

3. Operation usage:

1. This system consists of an operating console, a mobile handle (or foot switch), which facilitates on-site control by operators.

2. NC control, which can input the height of the lower roller (or the diameter size of the roll) through the touch screen, to achieve a series of actions such as loading, rolling, starting and stopping, flipping to material retrieval, etc.

4. Equipment continuous operating environment:

(1) Power range: three-phase AC380V ± 10% 50Hz;

(2) Environmental temperature: -10 ℃ -45 ℃;

(3) Relative humidity: ≤ 95%;

(4) Altitude: ≤ 2500 m

六、 List of Key Components:

If you need a plate rolling machine or are interested in a plate rolling machine, please provide the material of the plate, plate thickness (maximum thickness, minimum thickness), plate width (roll length), and minimum coil diameter. We will recommend a suitable plate rolling machine for you.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com