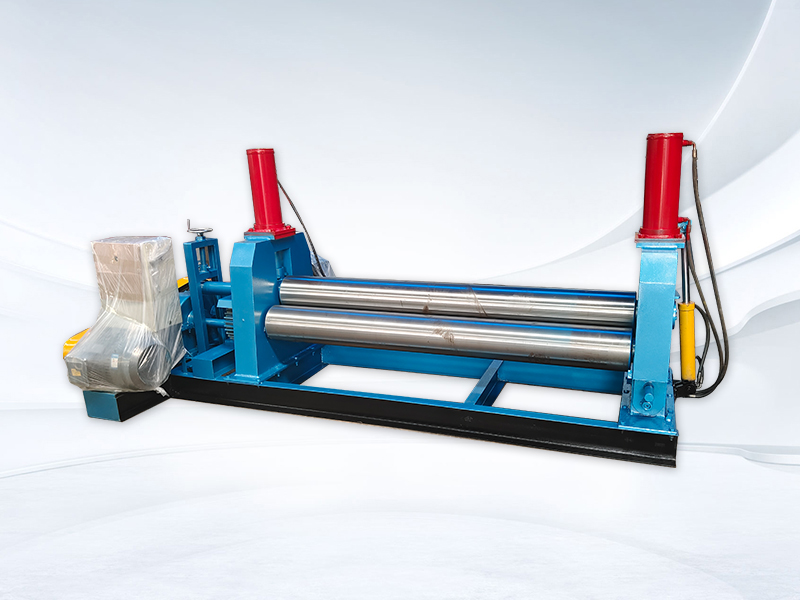

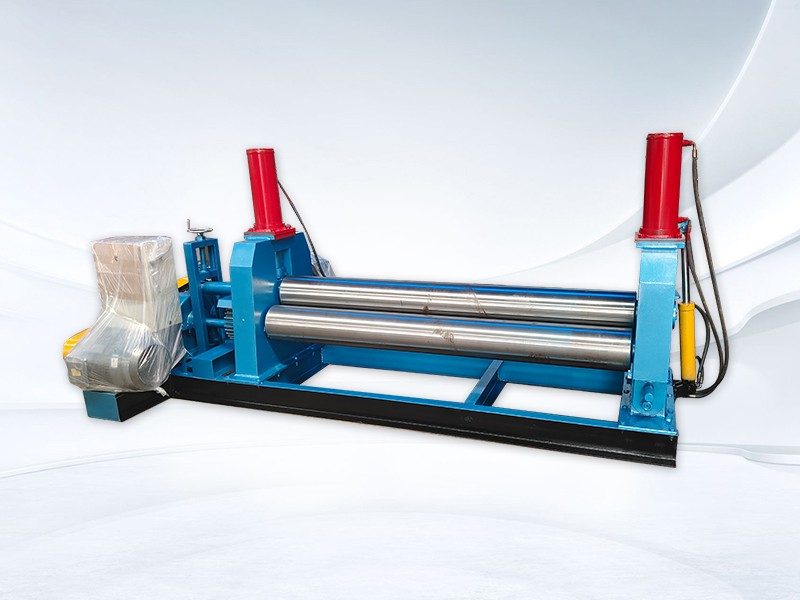

Technical Description of W11-20x2500 Simple Hydraulic Plate Rolling Machine

1、 Symmetrically adjustable three roll plate rolling machine

This machine belongs to the mechanical transmission three roll plate rolling machine, which is used to roll steel plates into cylindrical, curved, and conical shapes.

The upper and lower rollers are powered by hydraulic motors, hydraulic cylinders, and hydraulic stations, causing the sheet to bend and deform. The rolling transmission is driven by the main motor through the main reducer and open gear to rotate the lower roller, and becomes the main power source during plate rolling.

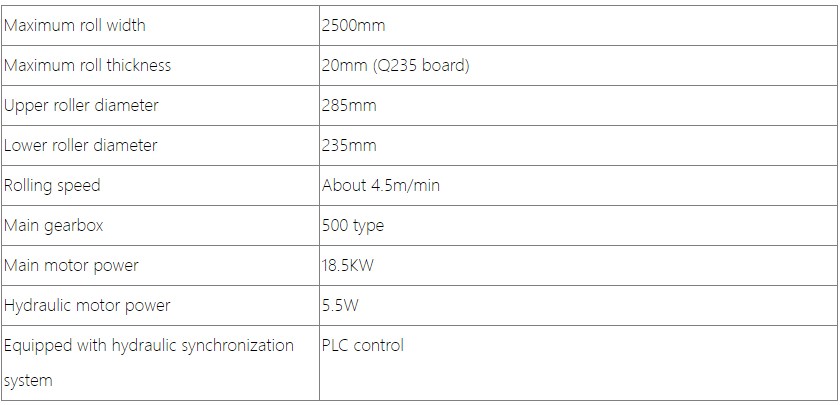

2、 Main parameters

3、 General standards for the design and acceptance of symmetrical upward three roll plate rolling machines

1. JB/T8796-1998 Precision of Plate Rolling Machine

2. JB/T3185.1-1999 Technical Conditions for Small and Medium sized Three roll Plate Rolling Machines

3. JB/T8797-1998 Types and Basic Parameters of Small and Medium sized Plate Rolling Machines

4. JB/T1829-1997 General Technical Conditions for Forging Machinery

5. GB 17120-1997 Safety Technical Conditions for Forging Machinery

6. JB/T5594-1992 General Technical Requirements for Assembly

7. GB/T5526.1-1996 General technical specifications for industrial machinery and electrical equipment

4、 Main body organization

The main structure of the equipment consists of an upper roller device, a pressing device, a lower roller device, a main transmission device, a flipping device, left and right side frames, and a base.

1. Upper roller device and pressing device

The upper roller device consists of an upper roller, an upper roller bearing seat, etc. Sliding bearings are installed on the bearing seats at both ends of the upper roller. The upper roller lifting is driven by a hydraulic cylinder, and the power is provided by a hydraulic station. The pressing device is powered by a hydraulic motor.

2. Lower roller device

The lower roller device consists of a lower roller, a lower roller bearing seat, a lower roller gear, and sliding bearings. The lower roller is the active roller, and the gear on the output shaft of the main transmission reducer drives the lower roller gear to transmit torque to the lower roller.

The material of the upper and lower rollers is 45 # steel, and the processing sequence is rough machining, quenching and tempering, precision machining, and surface heat treatment

3. Main transmission device

The main transmission device consists of a main motor, a gear reducer, and a hydraulic station.

4. Overturning device

It is mainly composed of a flip head body, a movable hinge, etc. The function of the flipping device is to facilitate the removal of the finished product.

5. Left and right racks, base

The left and right side frames and bases are welded steel plates and undergo aging treatment after welding.

5、 Electrical control system

The equipment electrical control system consists of an electrical control cabinet and a power supply. The forward and reverse rotation of the motor is controlled by AC contactors, and high-voltage control components including circuit breakers, fuses, contactors, thermal relays, buttons, switches, indicator lights, etc. are all selected from the national standard series products.

6、 Main features of the equipment

The equipment is made of welded steel plates, with high mechanical strength, precision, and practicality. The adjustment and operation of the parallelism between the upper and lower rollers are simple, and the equipment maintenance is convenient.

7、 Supply content

Equipment complete machine, equipment user manual, certificate of conformity

8、 Quality Assurance

The warranty period for the entire equipment is one year. If the motor or reducer malfunctions within one year, the manufacturer will replace them unconditionally.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com